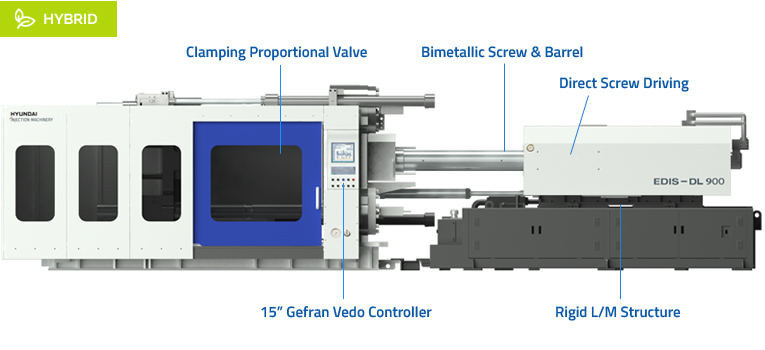

Cost effective two-platen direct lock

(1000~3300 US ton)

(1000~3300 US ton)

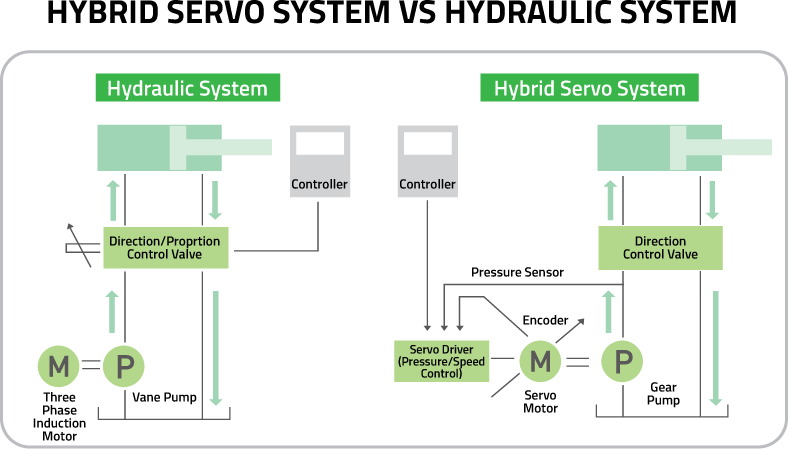

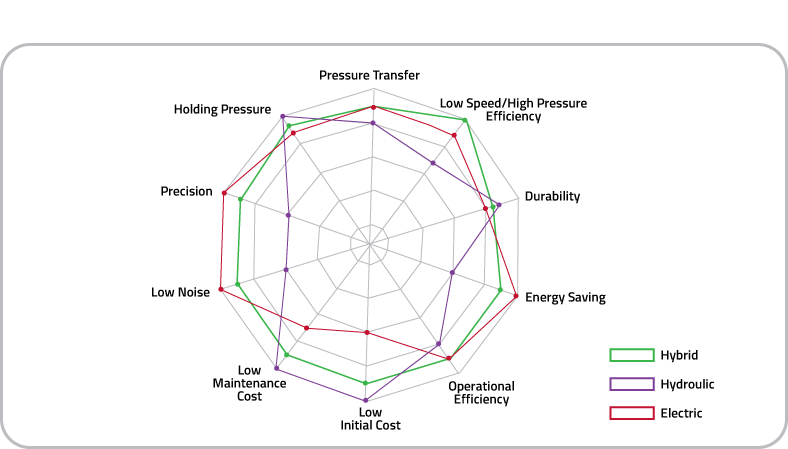

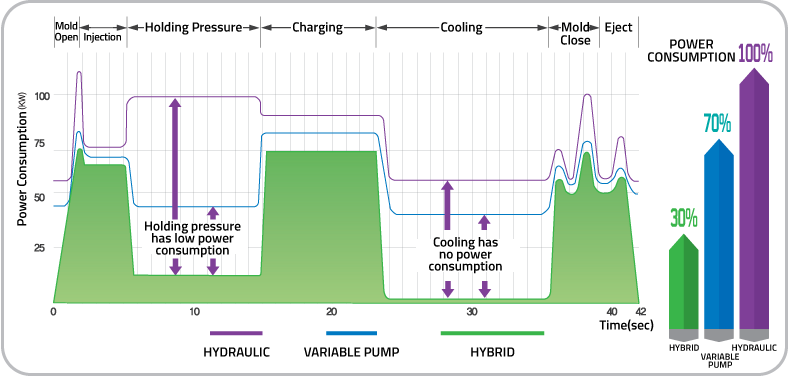

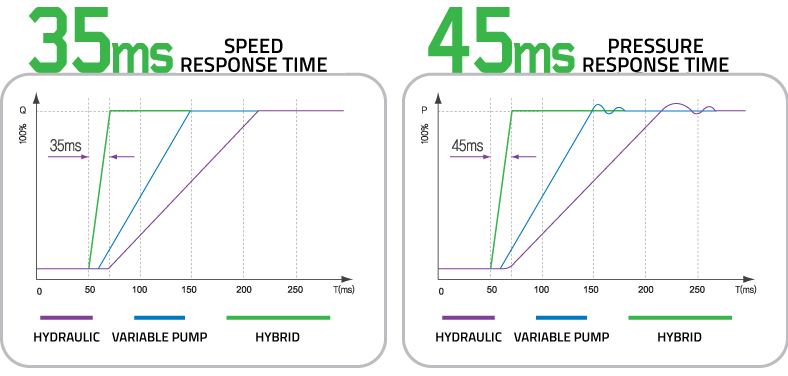

- Energy saving AC servo pump hybrid

- Rigid Platen Mechanism

- High Speed & Pressure Injection

- Direct Screw driving mechanism

| MODEL | EDIS-1000DL | ||

| Screw type | A | B | |

| Screw diameter | in | 4.33 | 4.72 |

| (mm) | (110) | (120) | |

| Injection capacity (PS) | oz | 184.6 | 219.7 |

| (g) | (5,232) | (6,227) | |

| Max. Injection pressure | Mpa | 167 | 140 |

| psi | 24,151 | 20,297 | |

| (kg/㎠) | (1,698) | (1,427) | |

| Clamping force | US ton | 990 | |

| kN | 8,826 | ||

| Clamping stroke | in | 72.8 | |

| (mm) | (1,850) | ||

| Tie bar clearance (H x V) | in | 52.0 x 44.1 | |

| (mm) | (1,320 x 1,120) | ||

| Platen dimension (H x V) | in | 71.7 x 63.0 | |

| (mm) | (1,820 x 1,600) | ||

| Daylight | in | 92.5 | |

| (mm) | (2,350) | ||

| Mold thickness | in | 19.7 ~ 53.1 | |

| (mm) | (500 ~ 1,350) | ||

| Machine dimension (L x W x H) | ft | 32.7 x 9.9 x 8.2 | |

| (m) | (9.96 x 3.01 x 2.50) | ||

| MODEL | EDIS-1150DL | ||

| Screw type | A | B | |

| Screw diameter | in | 4.33 | 4.72 |

| (mm) | (110) | (120) | |

| Injection capacity (PS) | oz | 184.6 | 219.7 |

| (g) | (5,232) | (6,227) | |

| Max. Injection pressure | Mpa | 167 | 140 |

| psi | 24,151 | 20,297 | |

| (kg/㎠) | (1,698) | (1,427) | |

| Clamping force | US ton | 1,155 | |

| kN | 10,297 | ||

| Clamping stroke | in | 72.8 | |

| (mm) | (1,850) | ||

| Tie bar clearance (H x V) | in | 54.7 x 46.9 | |

| (mm) | (1,390 x 1,190) | ||

| Platen dimension (H x V) | in | 74.8 x 66.9 | |

| (mm) | (1,900 x 1,700) | ||

| Daylight | in | 96.5 | |

| (mm) | (2,450) | ||

| Mold thickness | in | 23.6 ~ 53.1 | |

| (mm) | (600 ~ 1,350) | ||

| Machine dimension (L x W x H) | ft | 33.1 x 10.2 x 8.2 | |

| (m) | (10.10 x 3.12 x 2.50) | ||

| MODEL | EDIS-1300DL | ||

| Screw type | A | B | |

| Screw diameter | in | 4.33 | 4.72 |

| (mm) | (110) | (120) | |

| Injection capacity (PS) | oz | 184.6 | 219.7 |

| (g) | (5,232) | (6,227) | |

| Max. Injection pressure | Mpa | 167 | 140 |

| psi | 24,151 | 20,297 | |

| (kg/㎠) | (1,698) | (1,427) | |

| Clamping force | US ton | 1,320 | |

| kN | 11,768 | ||

| Clamping stroke | in | 72.8 | |

| (mm) | (1,850) | ||

| Tie bar clearance (H x V) | in | 53.4 x 45.7 | |

| (mm) | (1,360 x 1,160) | ||

| Platen dimension (H x V) | in | 74.8 x 66.9 | |

| (mm) | (1,900 x 1,700) | ||

| Daylight | in | 96.5 | |

| (mm) | (2,450) | ||

| Mold thickness | in | 23.6 ~ 53.1 | |

| (mm) | (600 ~ 1,350) | ||

| Machine dimension (L x W x H) | ft | 34.4 x 10.8 x 8.3 | |

| (m) | (10.50 x 3.30 x 2.52) | ||

| MODEL | EDIS-1450DL | ||

| Screw type | A | B | |

| Screw diameter | in | 4.72 | 5.12 |

| (mm) | (120) | (130) | |

| Injection capacity (PS) | oz | 239.6 | 281.2 |

| (g) | (6,793) | (7,972) | |

| Max. Injection pressure | Mpa | 168 | 143 |

| psi | 24,393 | 20,780 | |

| (kg/㎠) | (1,715) | (1,461) | |

| Clamping force | US ton | 1,430 | |

| kN | 12,749 | ||

| Clamping stroke | in | 72.8 | |

| (mm) | (1,850) | ||

| Tie bar clearance (H x V) | in | 56.3 x 56.3 | |

| (mm) | (1,430 x 1,430) | ||

| Platen dimension (H x V) | in | 78.7 x 78.7 | |

| (mm) | (2,000 x 2,000) | ||

| Daylight | in | 100.4 | |

| (mm) | (2.550) | ||

| Mold thickness | in | 27.6 ~ 53.1 | |

| (mm) | (700 ~ 1,350) | ||

| Machine dimension (L x W x H) | ft | 40.4 x 12.1 x 9.8 | |

| (m) | (12.30 x 3.70 x 3.00) | ||

| MODEL | EDIS-1800DL | ||

| Screw type | A | B | |

| Screw diameter | in | 5.12 | 5.51 |

| (mm) | (130) | (140) | |

| Injection capacity (PS) | oz | 308.9 | 358.2 |

| (g) | (8,757) | (10,157) | |

| Max. Injection pressure | Mpa | 148 | 128 |

| psi | 21,449 | 18,505 | |

| (kg/㎠) | (1,508) | (1,301) | |

| Clamping force | US ton | 1,760 | |

| kN | 15,691 | ||

| Clamping stroke | in | 94.5 | |

| (mm) | (2,500) | ||

| Tie bar clearance (H x V) | in | 63.8x 56.3 | |

| (mm) | (1,620 x 1,430) | ||

| Platen dimension (H x V) | in | 83.9 x 76.4 | |

| (mm) | (2,130 x 1,940) | ||

| Daylight | in | 129.9 | |

| (mm) | (3,300) | ||

| Mold thickness | in | 31.5 ~ 59.1 | |

| (mm) | (800 ~ 1,500) | ||

| Machine dimension (L x W x H) | ft | 40.4 x 12.3 x 11.2 | |

| (m) | (12.32 x 3.76 x 3.40) | ||

| MODEL | EDIS-2000DL | ||

| Screw type | A | B | |

| Screw diameter | in | 5.12 | 5.51 |

| (mm) | (130) | (140) | |

| Injection capacity (PS) | oz | 308.9 | 358.2 |

| (g) | (8,757) | (10,157) | |

| Max. Injection pressure | Mpa | 168 | 145 |

| psi | 24,322 | 20,965 | |

| (kg/㎠) | (1,508) | (1,301) | |

| Clamping force | US ton | 1,800 | |

| kN | 17,652 | ||

| Clamping stroke | in | 98.4 | |

| (mm) | (2,500) | ||

| Tie bar clearance (H x V) | in | 64.4 x 64.4 | |

| (mm) | (1,635 x 1,635) | ||

| Platen dimension (H x V) | in | 84.6 x 84.6 | |

| (mm) | (2,150 x 2,150) | ||

| Daylight | in | 129.9 | |

| (mm) | (3,300) | ||

| Mold thickness | in | 31.5 ~ 63.0 | |

| (mm) | (800 ~ 1,600) | ||

| Machine dimension (L x W x H) | ft | 41.7 x 13.1 x 11.2 | |

| (m) | (12.70 x 4.00 x 3.40) | ||

| MODEL | EDIS-2750DL | ||

| Screw type | A | B | |

| Screw diameter | in | 5.91 | 6.30 |

| (mm) | (150) | (160) | |

| Injection capacity (PS) | oz | 453.8 | 516.3 |

| (g) | (12,865) | (14,637) | |

| Max. Injection pressure | Mpa | 159 | 140 |

| psi | 23,013 | 20,226 | |

| (kg/㎠) | (1,476) | (1,298) | |

| Clamping force | US ton | 2,750 | |

| kN | 24,517 | ||

| Clamping stroke | in | 106.3 | |

| (mm) | (2,700) | ||

| Tie bar clearance (H x V) | in | 72.0 x 64.2 | |

| (mm) | (1,830 x 1,630) | ||

| Platen dimension (H x V) | in | 84.6 x 90.9 | |

| (mm) | (2,150 x 2,310) | ||

| Daylight | in | 141.7 | |

| (mm) | (3,600) | ||

| Mold thickness | in | 35.4 ~ 66.9 | |

| (mm) | (900 ~ 1,700) | ||

| Machine dimension (L x W x H) | ft | 47.6 x 14.1 x 12.1 | |

| (m) | (14.50 x 4.30 x 3.70) | ||

| MODEL | EDIS-3300DL | ||

| Screw type | A | B | |

| Screw diameter | in | 6.30 | 6.69 |

| (mm) | (160) | (170) | |

| Injection capacity (PS) | oz | 580.9 | 655.7 |

| (g) | (16,467) | (18,589) | |

| Max. Injection pressure | Mpa | 140 | 124 |

| psi | 20,226 | 17,921 | |

| (kg/㎠) | (1,298) | (1,149) | |

| Clamping force | US ton | 3,300 | |

| kN | 29,420 | ||

| Clamping stroke | in | 106.3 | |

| (mm) | (2,700) | ||

| Tie bar clearance (H x V) | in | 78.7 x 74.8 | |

| (mm) | (2,000 x 1,900) | ||

| Platen dimension (H x V) | in | 102.4 x 99.2 | |

| (mm) | (2,600 x 2,520) | ||

| Daylight | in | 145.7 | |

| (mm) | (3,700) | ||

| Mold thickness | in | 39.4 ~ 74.8 | |

| (mm) | (1,000 ~ 1,900) | ||

| Machine dimension (L x W x H) | ft | 45.6 x 15.1 x 13.5 | |

| (m) | (13.90 x 4.60 x 4.10) | ||

- All specs and dimensions are subject to change without notice or may differ depending on export destinations and manufactured year.

- E-Solution Inc is not responsible for any inaccuracies contained herein.

- Please consult our sales representative or our head office before designing a mold.

- Actual plasticizing capacity may vary, depending on the molding conditions and material used.